Every year, companies like yours contemplate what they are going to do with the workwear items they don’t need any more.

Uniforms are a key part of keeping staff safe and promoting your brand. They are a hugely necessary part of any business.

But, the fact of the matter is… they create waste.

And in a time when the world is trying to reduce the amount of waste created, generating a steady supply of guaranteed waste is not great.

Luckily, there is a solution.

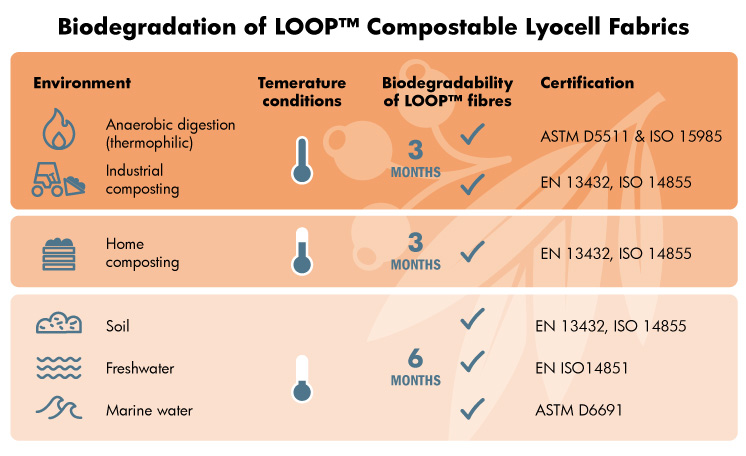

LOOP™ Compostable and Biodegradable Workwear is just as durable and effective as your usual varieties, but it is created from fully compostable or biodegradable fabrics. Yes, that’s right. In as little as 3 months, those unwanted uniform items could be returned to the earth. No waste, no problem!

Read on to find out more about what LOOP™ compostable and biodegradable workwear is and how it could be implemented in your business.

What Is The Difference Between Compostable And Biodegradable Fabrics?

Here at LOOP™ Workwear, we offer a number of sustainable fabric choices. The words biodegradable and compostable often get used interchangeably. While both are sustainable choices that will return to the earth in time, there are distinct differences between the two.

The word ‘biodegradable’ is a huge clue about what distinguishes these kinds of fabrics. To be biodegradable, something has to break down via a natural biological process. ‘Bio’ meaning life, ‘degrade’ meaning to break down, and ‘able’ meaning possible. If something is biodegradable, then it is able to break down in a landfill over time. LOOP offers biodegradable fabrics like organic cotton, merino and hemp.

Compostable fabrics are a little bit different. They need to be returned to the earth through a composting process. Typically, when placed in a composting situation, compostable fabrics are much faster to break down than any other fabric. In fact, they break down in the same short timeframe as paper would.

What is Composting?

Compost is a pretty powerful thing. Just like the process of adding conditioner to your hair, compost adds nutrients and rejuvenates soil, encouraging strong plant growth.

Composting used to be relegated to the realm of farming and keen gardeners. But in recent years, as we have been enlightened to the benefits, it is growing in popularity.

And, rightly so! Not only does composting boost plant production, but it also helps to deal with a growing global problem of waste.

Composting is designed to handle organic waste and could be a sustainable solution to your garment waste problem.

The Dangers Of Synthetic Fabrics

Traditionally, most workwear is made from synthetic fibres. Those are man-made fibres that are created through chemical processes, as opposed to natural fibres which occur naturally. Because of the widespread use of synthetics, 20% of the world’s waste comes from the apparel industry.

Synthetics make up 60% of all textiles produced. Fabrics such as polyester can take up to 200 years to break down. That means, your great-great-grandchildren could be dealing with the waste created by today’s polyester workwear!

It is not just the end of life we should worry about with synthetic fibres. The concern also lies with the creation process. It takes The creation process for synthetic fibres like polyester takes 550% more energy than organic cotton production. Plus, the yield of an organic fibre crop is more than 50% higher than its synthetic counterparts.

To us, those statistics simply aren’t good enough. So, we have made it our mission to reduce the problem by offering a practical and durable compostable solution.

How Can Clothes Be Compostable?

How can clothes be compostable? Won’t they fall apart after a while?

Nope, in fact, our compostable fabric is just as durable as standard workwear fabrics. As it is made from wood pulp fibres, it is strong and effective. However, when it is placed into compost, the composting process takes effect. Microorganisms break down solid, natural waste, turning them into finer pieces.

Until the time that composting happens, the fabric is a perfect easy-care option that can be washed and worn over and over.

Revolutionary Lyocell Fabric

The secret to our LOOP™ compostable workwear is the revolutionary Lyocell fabric that we use to make it. Lyocell is the world’s most sustainable, man-made fibre.

Lyocell is made from the wood pulp of fast growing gum trees. That pulp is then made into fibres via a low environmental impact process, which creates the Lyocell fabric. This is the fabric we use to create everything from shirts, vests and other garments. It can even be combined with our 100% recycled polyester fabric to make overalls and jackets.

Lyocell is naturally breathable, has no-shrinkage, is highly durable and has a cooling effect on the body. It is certified as 100% compostable in marine, industrial, home, and soil conditions.

Creating Effective Workwear Solutions

At LOOP™ Workwear, we are all about creating effective workwear solutions. So, it is important to us that our sustainable fabrics are comfortable, easy-care, durable and fade resistant.

We have a fully customisable range of shirts, polos, vests, jackets, and hi vis options to suit any business. They can be crafted in any colour and include logos, taglines or other branding aspects.

It really is the best solution for workwear. You get quality garments that last the distance. Then, once those garments have reached their end of life, they can be composted (or will naturally biodegrade) with no impact on the earth. There is no need to add to the load in current landfills any more.

If you would like to know more about how LOOP™ compostable and biodegradable workwear could be the solution for your company, then get in touch with us here at LOOP™ Workwear today.